| M. To Adjust Contacts.

- Release the locknut R

by means of the special spanner and turn Q so that the

contacts are closed when the slipper L is over a flat of

the cam, and open by the thickness of the, gauge spanner

when slipper is on a point of the cam.

- Are contact surfaces badly pitted?

Yes. This is unlikely to cause complete failure whilst

running unless they are badly burned away. Sparking at

the contacts to such an extent as to pit them badly is a

sign of faulty connection to the condenser, or that the

contacts are worn down to the base metal. Be sure that

the screws holding the condenser in position are not

slack.

Note. A fault in the condenser itself causing a short

circuit would not cause sparking but would put the

contact breaker electrically out of action.

N. To Renew Condenser.

- The condenser cannot be inspected or repaired. If

it is faulty the entire tray must be removed, the

condenser taken off and replaced with a new one.

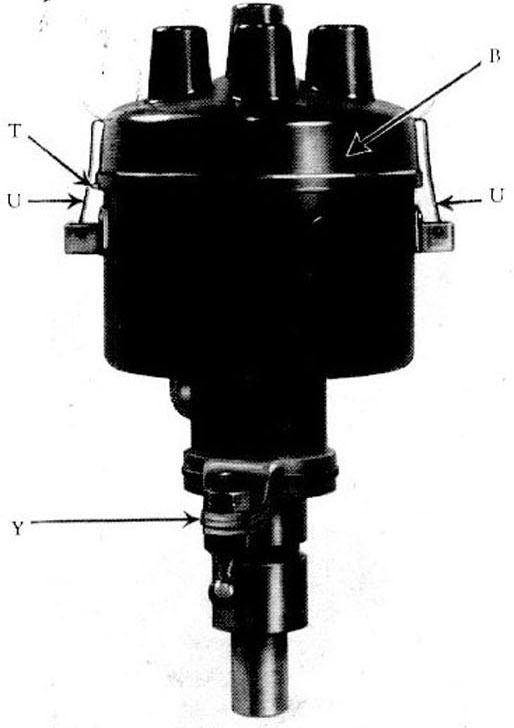

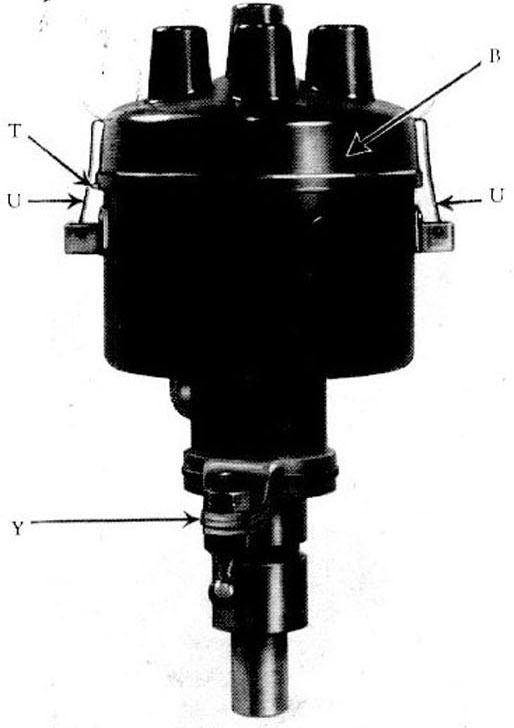

O. Replacing Distributor Arm and Cover.

- When replacing distributor arm D, remember it can

only fit properly into position when the flat on its

underside registers with the flat on the spindle

immediately above the cam M.

- When replacing distributor cover be sure that the

projecting dowel T on the casing registers properly with

the niche O in the circumference of the cover. The

springs U, which secure the cover, snap into place most

easily when pressed in the middle.

|

|