If the contacts do not open or do not close properly

the fault is due to either:

(i) Contact arm cracked.

(ii) Contact arm not moving freely.

(iii) Contact arm slipper worn

(iv) Contact require adjustment

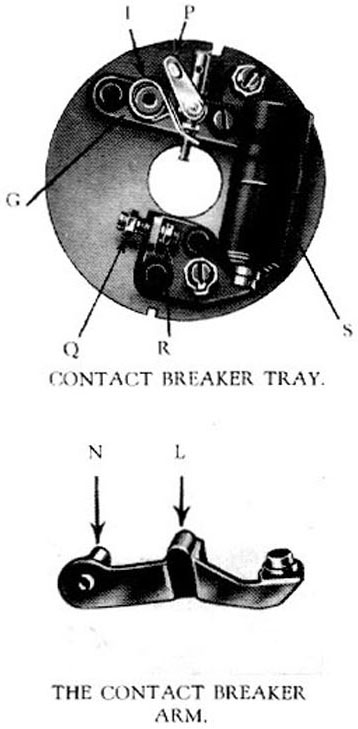

K. Inspecting Contact Arm.

- Does the contact arm fly back freely when pulled

back and released?

If it sticks apply a spot of thin oil to its pivot

N about which it rocks.

If it still sticks, remove the contact arm as

follows:-

L. To Remove Contact Arm.

- Disconnect the low tension and earthing wires.

- Release the springs U and the fastening plates H

inside the casing, by taking out the four screws V. Lift

the contact breaker tray out of the casing. Care must be

taken that the lubricating wick is not forced out by its

spring.

Note. In replacing the tray it is important to see

that the dowels W in the casing are properly located

in the corresponding slots in the tray.

- Push the spring clip P away from the contact arm

pivot at N.

- Hold the spring I clear with a bradawl and lift

the contact arm off the tray.

|