|

Diagnosis of trouble

The following instructions relating to testing the distributor

and contact breaker in the event of trouble being traced to

them, should be substituted for those given in the

Instruction book :-

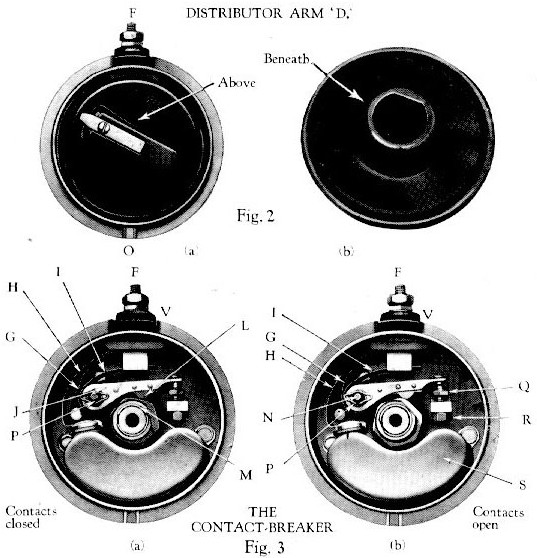

Testing Distributor

- Release the springs U and remove the distributor cover B (without removing the

high tension cables therefrom). Inspect the central carbon brush C to be sure that

it moves freely so that it will make contact with the revolving distributor arm D.

Make sure that all the high tension cables are properly connected to the terminal

sockets on the distributor cover. Also see that the inside of the cover is clean

and dry. If the cover is in order the fault lies in the contact breaker.

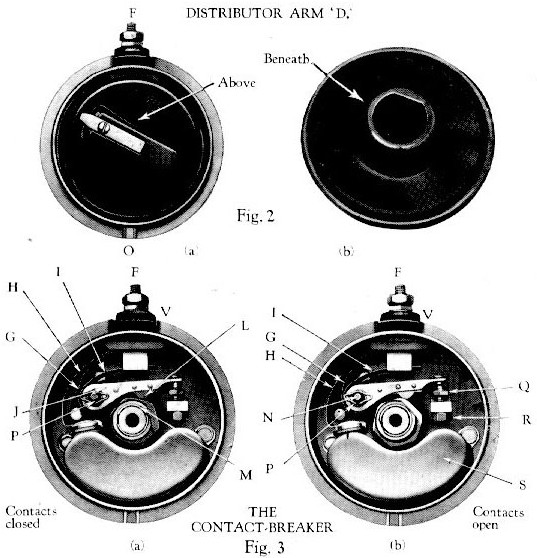

Testing the Contact Breaker

- Is the low tension terminal F properly fastened to the case? Is its insulation intact?

- Are the middle and outer conductor strips G H (Figs. 3a and 3b)

to the contact arm J and condenser S intact

and properly gripped by the metal of the low tension

terminal?

- Is the spring I controlling contact arm intact?

- Is the contact arm J itself intact and free from

any crack?

- Do the contacts close when the slipper L on the

arm is over the flat of the cam M? The slipper should be

clear of the cam to allow the contacts to close.

|