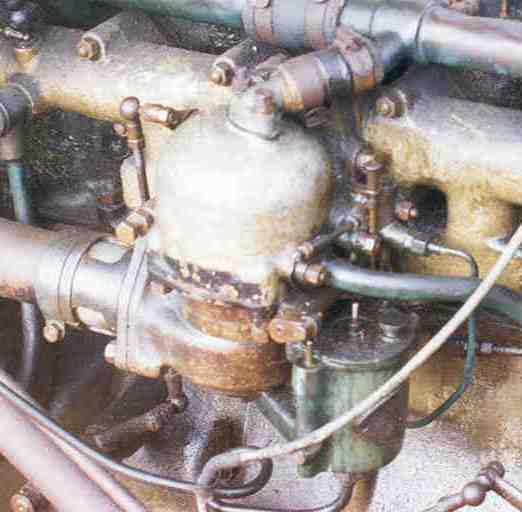

The Daimler carburettor is a most unusual device to those brought up with Zeniths and Strombergs.

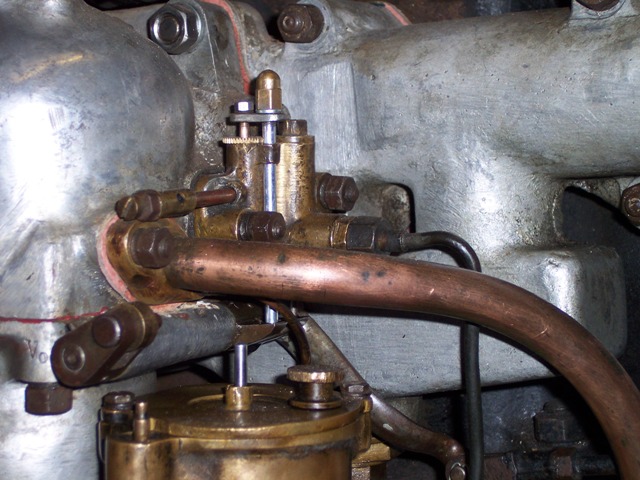

For a start, not only petrol is fed to the area. The main chamber of the carburettor is surrounded by a water jacket. The fuel in 1927 was not of very high quality. Petrol stations were a new concept and most fuel would have been shipped in cans. The water jacket warms the mixture before it reaches the manifold, which has a copper pipe running through it with more hot water.

The petrol primer supplies petrol to a jet in the manifold, and operated at the same time is an oil primer, to ensure that the sleeve valves are well lubricated during starting. This can also be operated when the car is en route, after climbing steep hills, for example.

All three vital fluids in one place!

The carb was dismantled bit by bit. The float chamber is connected to the base of the main body where the jets reside. The jets had sufferred a little:

There are five identical jets - the 35/120 carburettor has seven. We carefully straightened the thin-walled tubes using a ring spanner.

The base of the main body has a throat plate through which these jets point. We carefully centred the jets in their holes.

Above this plate sits the barrel, reminiscent of that in a revolver.

Covering this is a weighted cup, which is very close-fitting.

When I first dismantled the carb, I removed the barrel from the body, then wondered what to do with it. Maybe this black cover unscrews, I thought. A little force cracked the seal formed by the dried petrol of sixty years ago. Covering the air hole with my thumb, I allowed the cup to sink. It took a whole minute. These things were machined VERY accurately.

The operation of the unit is simple. The engine is started using the primer. Once the engine is running, the vacuum pressure in the inlet manifold increases. As it does, the weighted cup lifts, uncovering progressively more holes in the barrel, thus admitting more fuel and more air. Of course response is not instantaneous as it is on a modern car!

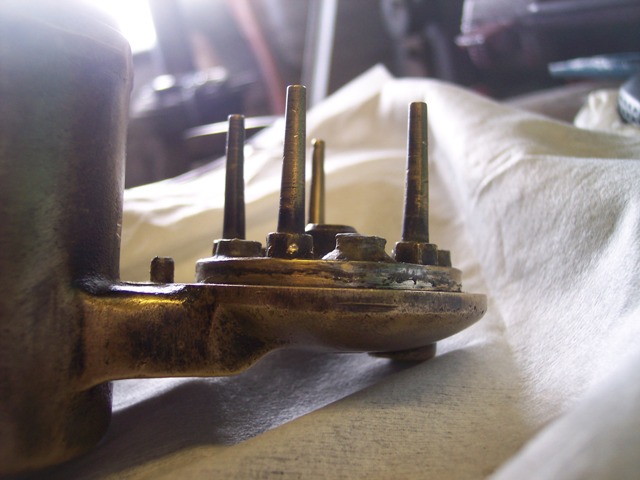

We then found that the petrol primer was not operating properly. The primer is operated by a rotating rod which has a flap for each of the primers. The oil primer opens a valve directly. The petrol primer is pulled up from above. A rod and cross-piece transmit the action.:

We compared the primer with the small illustrations in the manuals. Very similar, except the air inlet pipe on ours was not bent upwards like the official version. But examine that rod closely. It is not the official part after all - it's part of a wheel spoke! A get-you-home repair.

A replacement was machined, complete with adjustment screw.